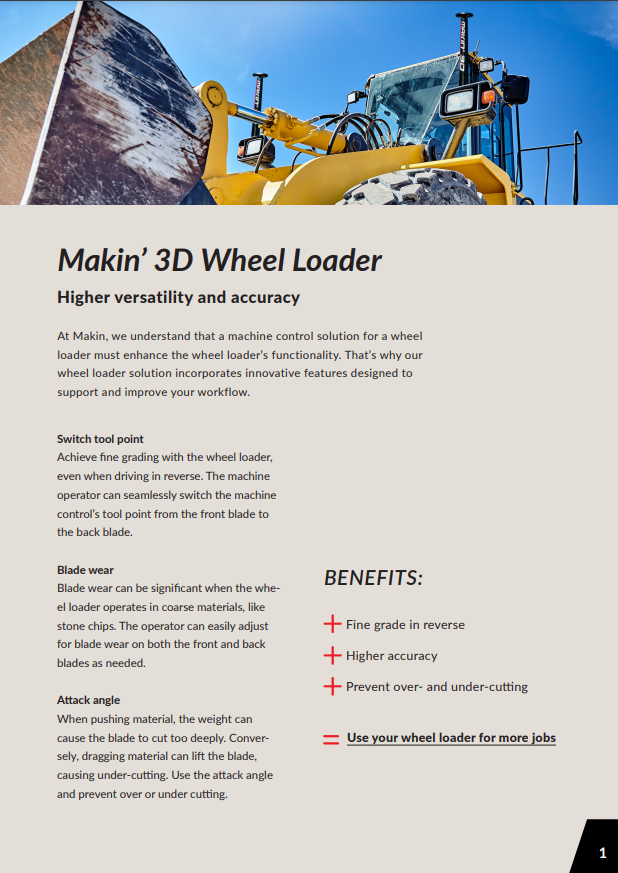

Makin’ Wheel Loader

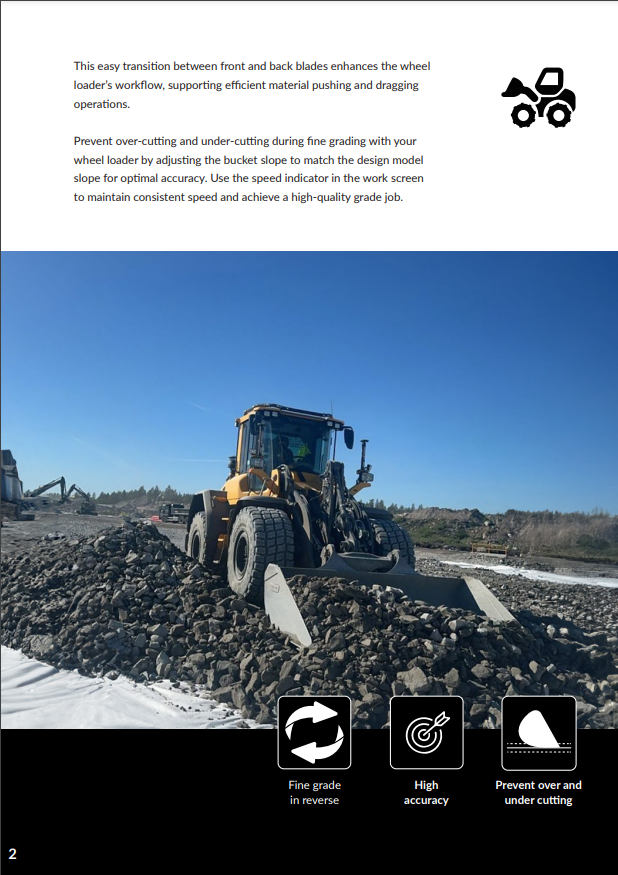

Makin’s wheel loader solution incorporates innovative features designed to support and improve your workflow. This easy transition between the front and the back of the blade enhances the wheel loader’s efficient pushing and dragging of material. Prevent over-cutting and under-cutting by adjusting the bucket slope to match the design model slope, and use the speed indicator in the work screen to maintain consistent speed and achieve a high-quality grade job.

Switch Tool Point

Achieve fine grading with the wheel loader, even when driving in reverse. The machine operator can seamlessly switch the machine control’s tool point from the front blade to the back blade.

Blade Wear

Blade wear can be significant when the wheel loader operates in course materials, like stone chips. The operator can easily adjust for the blade wear on both the front and back blades as needed.

Attack Angle

When pushing material, the weight can cause the blade to cut too deep. Conversely, dragging material can lift the blade causing under-cutting. Use the attack angle and prevent over or under cutting.

One Platform

Use the tablet between applications. With only one system to learn, it makes it very intuitive to switch between, wheel loader, survey, excavator, tool guidance, and performans. Minimising training time.